For more than 150 years, manufacturing companies led by local families have been a key component of Chattanooga’s economy. From Chattanooga Medicine Company (now Chattem; founded by Zeboim Cartter Patten in 1879) to Coca-Cola Bottling Company (co-founded by John Thomas Lupton, Joseph Whitehead, and Benjamin Thomas in 1899) to Siskin Steel and Supply Company (founded by Robert Siskin in 1900), family-led manufacturers have prospered and provided employment in the Chattanooga area for over a century.

And yet, this prosperity did not come without challenges. Changing economic times, shifting consumer preferences, and global competition were just a few of many obstacles faced by company executives in their decades of leadership. Confronted with an ever-changing market, these leaders were forced to adapt, innovate, and when needed, even change their business models to survive.

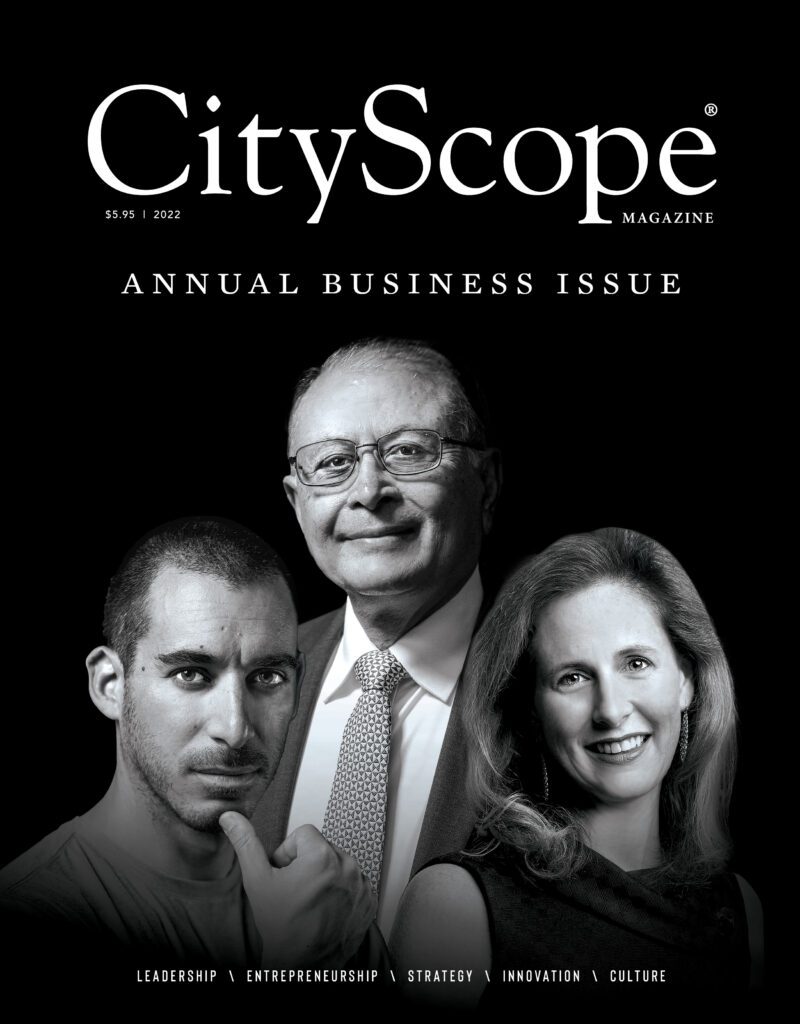

Here, we profile five manufacturing companies that have flourished in the Chattanooga area for decades. Led by generations of local families, these companies have continued to grow and expand due to their ability to invent and reinvent what they do best. For some, that involved introducing new products and pursuing new markets. For others, it was about acquiring other companies, streamlining operations, and adopting new technologies.

For all, it required adapting to survive and thrive.

Cast iron cookware is known for its excellent ability to withstand high heat – and you could say the same for Lodge Manufacturing. The South Pittsburg-based manufacturer is now celebrating 120 years, making it the only century-old American cast-iron cookware company to survive into the new millennium.

Joseph Lodge founded the company as “Blacklock Foundry” in 1896, but just 14 years later it burned to the ground. However, that wasn’t the last the world would hear of Lodge. Out of the ashes came Lodge Manufacturing Company in 1910, and the company has stayed in the family ever since.

As the years passed, Lodge Manufacturing stayed above ground by maintaining high standards of innovation, conservation, and technology. When electric power began gaining ground in the early 20th century, the company switched from steam-powered to electric-powered motors. When the Great Depression hit, the company added more items to its product lines – such as doorstops – to keep the furnaces burning. When the post-war years brought increased demand, the company ramped up production by automating and streamlining processes.

In the early ’90s, Lodge updated its foundry and replaced the coal-fired cupola furnaces with an electro-magnetic induction melting system – earning the company a Governor’s Award for Excellence in hazardous waste reduction. Then in 2002, the company grew from a regional distributor to a national household name when it introduced Lodge Logic, its foundry-seasoned cookware line. Lodge Logic eliminated the hassle of its unseasoned counterparts, earning it positive reviews from Good Housekeeping and other consumer magazines for product innovation.

“Chefs and consumers have always used cast iron cookware,” explains Mark Kelly, public relations and advertising manager. “But once our products became available already foundry-seasoned, it changed the whole ball game.”

Today, the company continues its reputation for quality under the leadership of Joseph Lodge’s great-grandsons Henry Ware Lodge (president and CEO) and Robert Finch “Bob” Kellermann (chairman of the board and CEO emeritus). And while it remains in the same 1910 facility, it has expanded its product catalog to include over 200 items. Just last year, the company increased manufacturing capacity by 50 percent – its largest expansion to date. A second expansion slated for later this year will double manufacturing capacity again.