Over the last century, this industry has experienced highs and lows. However, through the waves of economic ups and downs, the perseverance, innovative spirit, and exceptional strategic moves by family businesses have led the carpet industry to great heights, serving flooring needs around the world.

Over the last century, this industry has experienced highs and lows. However, through the waves of economic ups and downs, the perseverance, innovative spirit, and exceptional strategic moves by family businesses have led the carpet industry to great heights, serving flooring needs around the world.

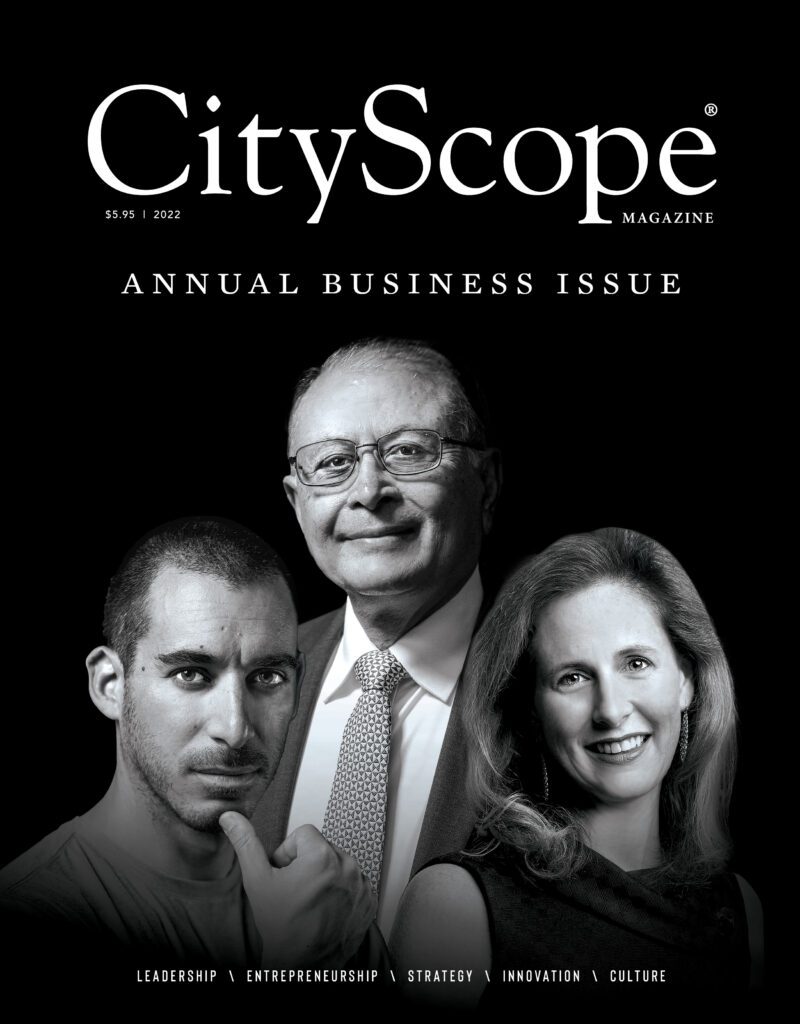

By George Christian and Alexandra Hruz

Photo above by Laura McNutt

The Thread of History

The Thread of History

The 19th Century—The South and Tufting

The first U.S. carpet industry emerged at the end of the eighteenth century. Skilled weavers produced carpets and rugs with handloom technology. Americans used carpet to cover poor quality, soft wood floors. In the early 1840s, power looms began to replace handlooms.

While production for carpet was centered in the Northeast and manufactured with wool by handloom and emerging power loom technology, the South emerged as the center for carpet production using new tufting technology and nylon fabric.

The rise of the South began in the 1890s when Catherine Evans Whitener created a hand-crafted bedspread using hand tufting. She gifted the spread to a newly wedded couple, and interest in her design grew.

As demand increased exponentially for Whitener’s bedspreads, local families were recruited to help with the hand tufting. Some estimates say that nearly 10,000 area cottage tufters, including men, women, and children, were involved in the sewing process. From Tennessee down through Georgia, the popularity of bedspreads grew to such a level that U.S. Highway 41 was often referred to as “Bedspread Alley.”

1910s, ’20s and ’30s

The story of the North and the South continued into the 20th century. Large rugs produced by Northeastern manufacturers became a staple in upper middle-class American homes. Sales grew dramatically, but peaked in 1923 and then steadily fell off as the economy slowed leading up to the Great Depression.

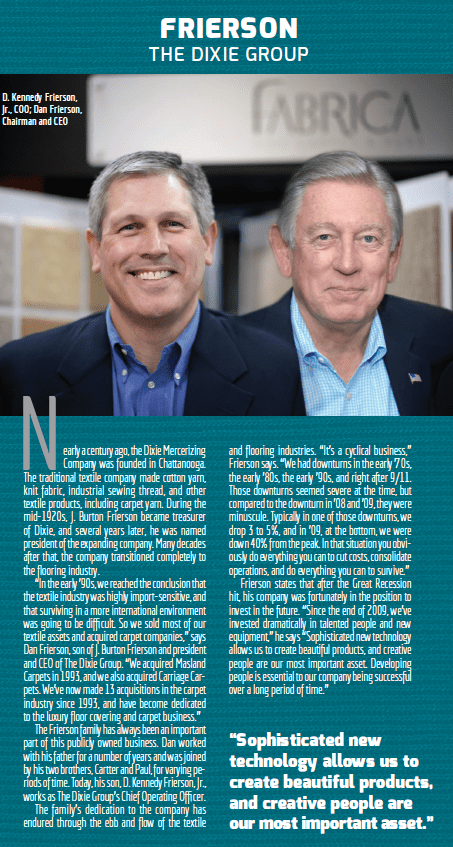

The South was a different story. After the Civil War, Southern manufacturers borrowed Northern technology, and initiated what might be called a process of regional learning to purposefully industrialize the region. By the early twentieth century, the South still had not developed a regional textile machine-making industry, but cotton mills, hosiery mills, and other textile firms established solid, skilled workforces knowledgeable in the technologies used by Northern manufacturers. Thread, cotton, and hosiery mills in Chattanooga and Georgia (including the Dixie Mercerizing Company, which would become The Dixie Group) created fibers that were used for a variety of products. By the ’20s, the South was manufacturing the majority of the United States’ textiles.

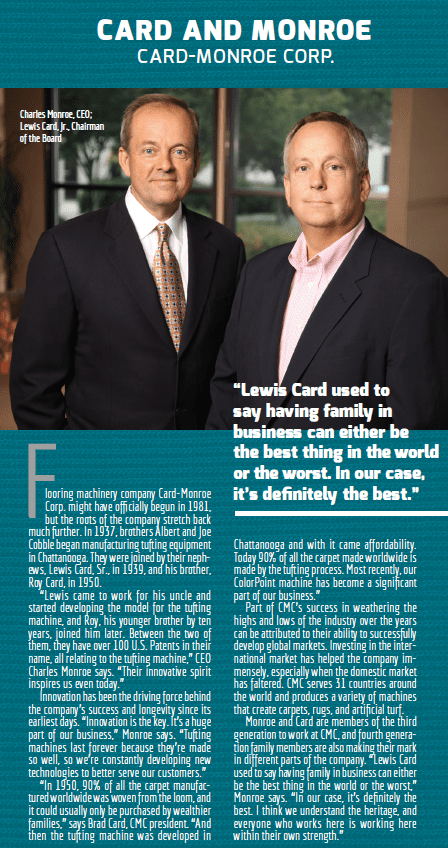

By the 1930s, a number of firms were experimenting with multi-needle machines that could tuft wider swaths of backing material more quickly. Southern firms began making small rugs by covering the entire surface of a piece of backing material with tufts. Albert and Joe Cobble founded firms in Chattanooga to build special machines for the tufted bedspread and small rug industry. Utilizing the new technology, area entrepreneurs began experimenting with making large rugs and wall-to-wall carpeting with the tufting process.

1940s and ’50s

With the ’40s came World War II and during this time, most mills in the area transitioned to war production. Following the war, the U.S. economy entered a prolonged boom period that many historians have labeled the “golden age.” The release of pent-up consumer demand led to an unparalleled housing boom and economic growth.

During this period, the Cobble Brothers firm from Chattanooga and an innovative Dalton spread making company, Cabin Crafts, introduced tufting machinery wide enough to produce carpeting in a single pass. The wholesale price of tufted carpet was about half that of woven products produced by Northern manufacturers. Sales for new tufted carpets and rugs grew dramatically in the late 1940s and through the ’50s.

Northeastern carpet manufacturers struggled. Sales for woven goods, despite the greatest economic boom of all time, slipped to levels seen in the early 1900s. Frustrated, many Northern carpet mills began to open new plants in the South to take advantage of the region’s lower labor costs and pro-business state governments. Bigelow, Mohawk, and other Northeastern companies built facilities in Virginia, South Carolina, Georgia, and Mississippi during the 1950s. The new state-of-the art facilities used the latest and most productive looms, but their woven carpets were still too expensive.

While woven carpets struggled, the tufted carpet industry experienced a meteoric rise in

the 1950s. In addition to being less expensive than woven carpets, bulked continuous filament (BCF) nylon provided the tufting industry with the fabric needed to ensure a long-lasting quality product. By the end of the 1950s, the new tufted carpet industry had raced past the old woven industry. Most carpets were manufactured in the Southeast and most were made on tufting machines from synthetic materials like nylon.

1960s

The ’60s was a decade of continued economic progress. The median family income

rose from $8,540 in 1963 to $10,770 by 1969. Baby boomers aged 25 to 34 increased fourfold and were marrying, buying homes, and renting apartments. Home building and commercial housing skyrocketed and with it came a rapid expansion in the carpet industry in the late ’60s and early ’70s.

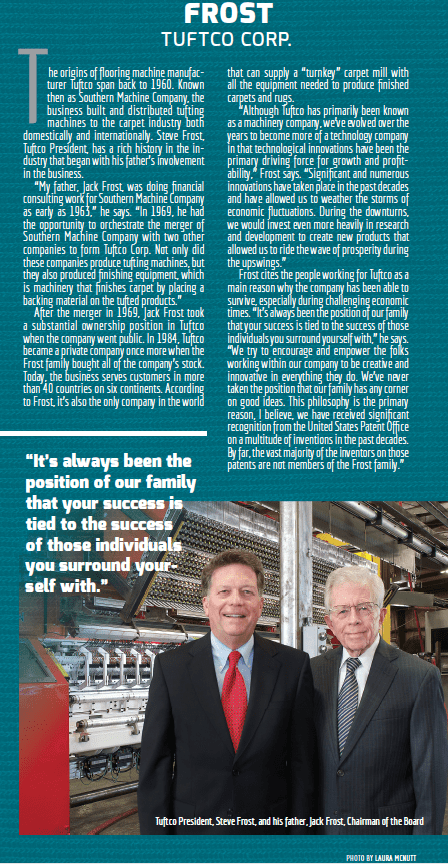

By 1965, carpet volume increased to more than three times the level in 1955, and tufted carpet sales accounted for all of the growth. Carpet sales continued to grow, surpassing one billion square yards in 1973. During this time, the industry was the fourth fastest growing among all business sectors, surpassed only by aircraft, television picture tubes, and computers. Southern Machine Company, the business that would become Tuftco Corp., was founded in 1960 to produce and distribute tufting machines for the burgeoning carpet industry.

1970s

As the national economy faltered behind the oil embargo of 1973, an oil shortage in 1978, and record interest rates, so too did the housing market. With this economic pull back, the carpet boom of the previous decades deflated. Revenue stalled and profits shrank. In an effort to restore shrinking profits, carpet manufacturers retrofitted plants with advanced, high-speed equipment to lower production costs and vertically integrated in an effort to lower raw material costs.

1980s

The troubles for the carpet industry didn’t end in the ’70s. Faltering savings and loan banks and high interest rates led to another recession that rocked the country in the early 1980s causing nearly half of the mills to close. Larger companies with cash earned during the ’60s and ’70s bought competitors and continued to vertically integrate.

1990s

The 1990s began with the Gulf War and a recession that lasted from July 1990 until March 1991. But the balance of the decade was one of strong economic growth, steady job creation, low inflation, rising productivity, and a surging stock market. With the improving economy, the carpet industry grew as housing starts increased and optimistic consumers redecorated and remodeled homes.

By the late ’90s, the carpet industry was heavily focused in the Southeast, with $8 billion of the industry’s $11 billion in wholesale sales and 32,000 of the industry’s 50,000 workers located in Georgia. Industry consolidation continued and smaller mills closed. The top four firms accounted for more than 80% of total production by the early 1990s. Tufted carpet had achieved total dominance.

2000s

As the 21st century began, the U.S. economy faltered, job creation slowed, the stock markets declined, and the country entered into a recession in 2001. The attack on New York’s World Trade Center, wars in Afghanistan and Iraq, and an escalation of terrorism created a business climate of uncertainty. Rising oil prices and the financial crisis of 2007 and 2008 led to a global decline of stocks and commodities and the Great Recession. Demand for all types of flooring went into massive decline, causing carpet makers and flooring producers to cut back on production, resulting in massive lay-offs.

As the U.S. enters the second decade of the 21st century, the economy has begun to recover. Since 2009, U.S. GDP has averaged a 2 to 3% increase per year. This growth, along with shrinking consumer debt, increased wealth, and low interest rates, have led to higher levels of residential and commercial construction and remodeling and a rebound in the carpet and flooring industry. Most industry experts believe that this industry will experience moderate but steady growth, with the U.S. economy and international markets playing a key role in continued long-term success.

Undoubtedly, the families who have led these companies, or those who have learned from them, will continue to chart the path of this great industry to new heights.